Solid oxide

electrolysis cells (SOECs), a key technology for producing green hydrogen

without carbon emissions, require a high-temperature ¡°sintering¡± process to

harden ceramic powders.

Researchers at KAIST have successfully shortened this

process from six hours to just ten minutes, while also reducing the required

temperature from 1,400¡ÆC to 1,200¡ÆC.

This innovation dramatically cuts both

energy consumption and production time, marking a major step forward for the

green hydrogen era.

KAIST announced on

Oct. 25 that a research team led by Professor Kang Taek Lee from the Department

of Mechanical Engineering has developed an ultra-fast manufacturing method

capable of producing high-performance green hydrogen electrolysis cells in only

ten minutes.

The core of this

technology lies in sintering—a process in which ceramic powders are baked at

high temperatures to form a dense, tightly bonded structure.

Proper sintering

is critical: it ensures that gases do not leak (as hydrogen and oxygen mixing

could cause explosions), oxygen ions move efficiently, and the electrodes

adhere firmly to the electrolyte to allow smooth current flow. In short, the

precision of the sintering process directly determines the cell¡¯s performance

and lifetime.

To address these

challenges, the KAIST team applied a ¡°volumetric heating¡± technique that uses

microwaves to heat the material uniformly from the inside out.

This approach

shortened the sintering process by more than thirtyfold compared to

conventional methods. Whereas traditional sintering requires prolonged heating

above 1,400¡ÆC, the new process uses microwaves to heat the material internally

and evenly, achieving stable electrolyte formation at just 1,200¡ÆC within 10

minutes.

In conventional

fabrication, the essential materials—ceria (CeO©ü) and zirconia (ZrO©ü)—tend to

intermix at excessively high temperatures, degrading material quality.

KAIST¡¯s

new method allows these two materials to bond firmly at the right temperature

without mixing, producing a dense, defect-free bilayer electrolyte.

The total ¡°processing

time¡± includes heating, holding, and cooling. The conventional sintering process

required about 36.5 hours, whereas KAIST¡¯s microwave-based technique completes

the entire cycle in only 70 minutes—over 30 times faster.

__images_000111_002_12.jpg)

Figure 1. (a) Schematic illustration of the microwave-based ultrafast sintering process and the conventional sintering process (b) Cross-sectional SEM images of the bilayer ceramic electrolyte according to the sintering process

The resulting electrochemical cells demonstrated remarkable performance: they produced 23.7 mL of hydrogen per minute at 750¡ÆC, maintained stable operation for over 250 hours, and exhibited excellent durability.

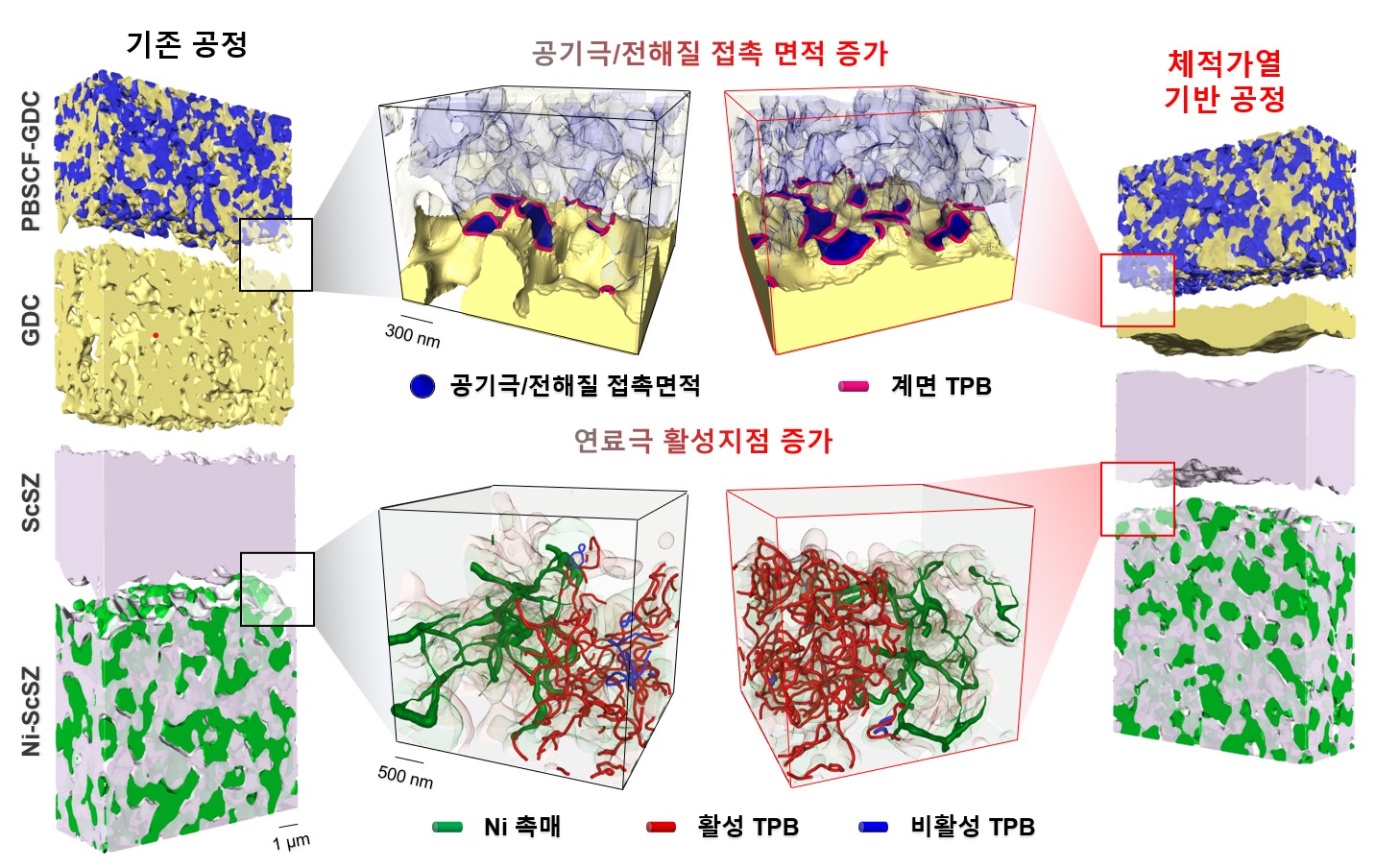

Using 3D digital twin simulations, the team further revealed that ultra-fast microwave heating improves electrolyte density and suppresses abnormal grain growth of nickel oxide (NiO) particles within the fuel electrode, thereby enhancing hydrogen production efficiency.

Figure 2. 3D reconstruction, contact area, and electrochemically active site images of the solid oxide electrochemical cell according to the sintering process

Professor Kang Taek Lee stated, ¡°This research introduces a new manufacturing paradigm that enables the rapid and efficient production of high-performance solid oxide electrolysis cells.¡±

He added, ¡°Compared to conventional processes, our approach drastically reduces both energy consumption and production time, offering strong potential for commercialization.¡±

This study was co-first-authored by Hyeongmin Yu and Seungsoo Jang, both Ph.D. candidates in Mechanical Engineering at KAIST, with Donghun Lee and Gayoung Youn as collaborators.

The research was published online on October 2 in Advanced Materials (Impact Factor: 26.8) and was selected as the Inside Front Cover feature paper for its scientific significance.

¡Ø Paper title: ¡°Ultra-Fast Microwave-Assisted Volumetric Heating Engineered Defect-Free Ceria/Zirconia Bilayer Electrolytes for Solid Oxide Electrochemical Cells¡±, DOI: 10.1002/adma.202500183)

Advanced Materials Inside Front Cover

This work was supported by the Ministry of Science and ICT through the H2 Next Round Program, the Mid-Career Researcher Program, and the Global Research Laboratory (GRL) Program.